PRODUCTS

Reduction of dust emission during the filling of crop silos

To significantly reduce the dust emission during the gravity filling of vertical metal silos, we have developed a system suitable for implementing two-stage dust separation.

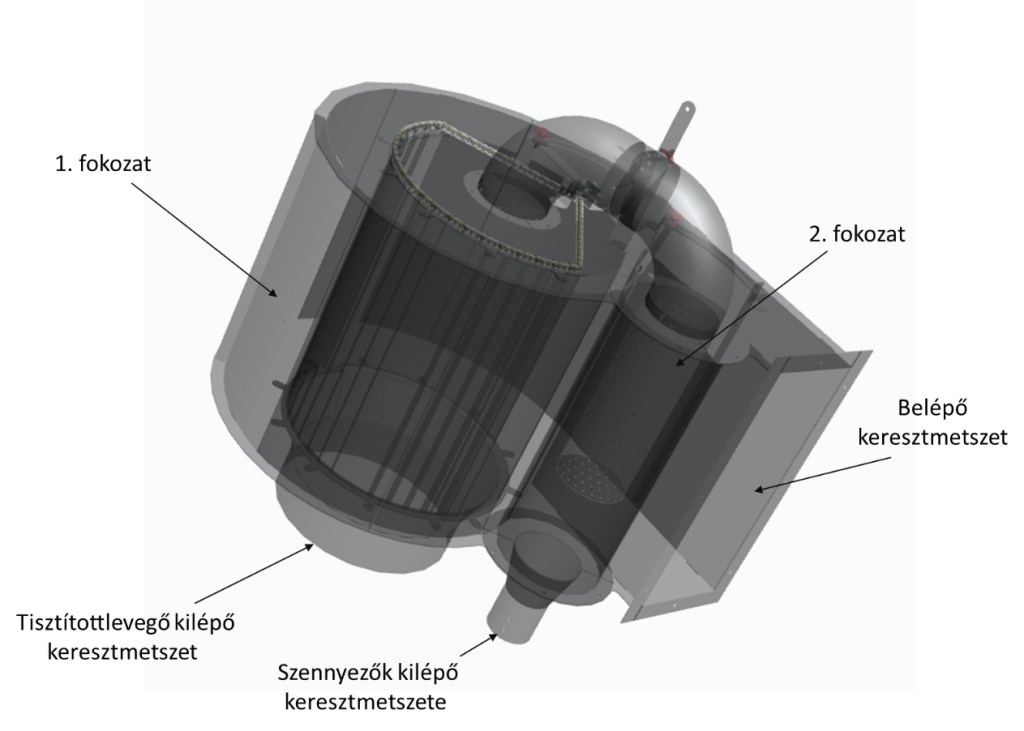

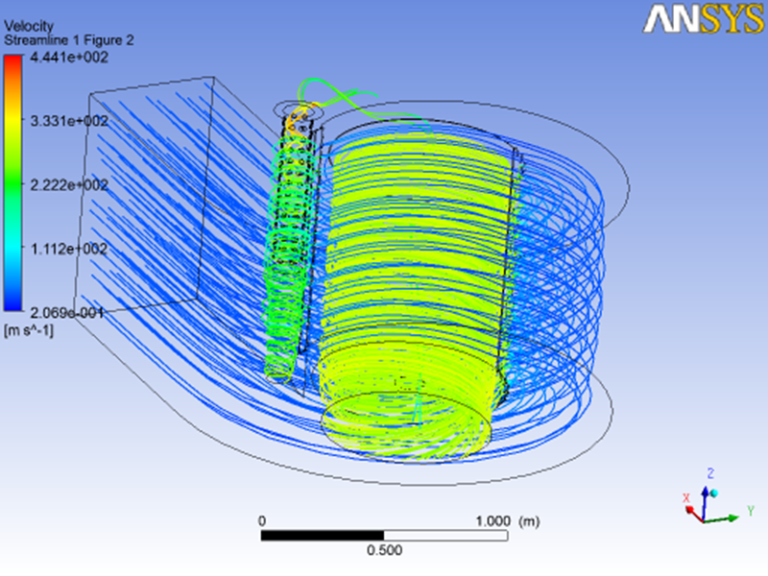

The first stage, with centrifugal flow, is connected to the inlet cross-section of the separator, while the second stage, with vortex flow, is connected to the contaminant outlet. In other words, the first and second stages are connected in series with respect to the flow of contaminants.

Concept of the two-stage centrifugal solid particle separator

Concept of the two-stage centrifugal solid particle separator

The first stage has a continuously narrowing space, defined by an internal and external casing in a spiral shape, with the internal casing partially designed like a damper.

For effective separation, it is advisable to connect a system with a minimum airflow capacity of 11,000 m³/h.

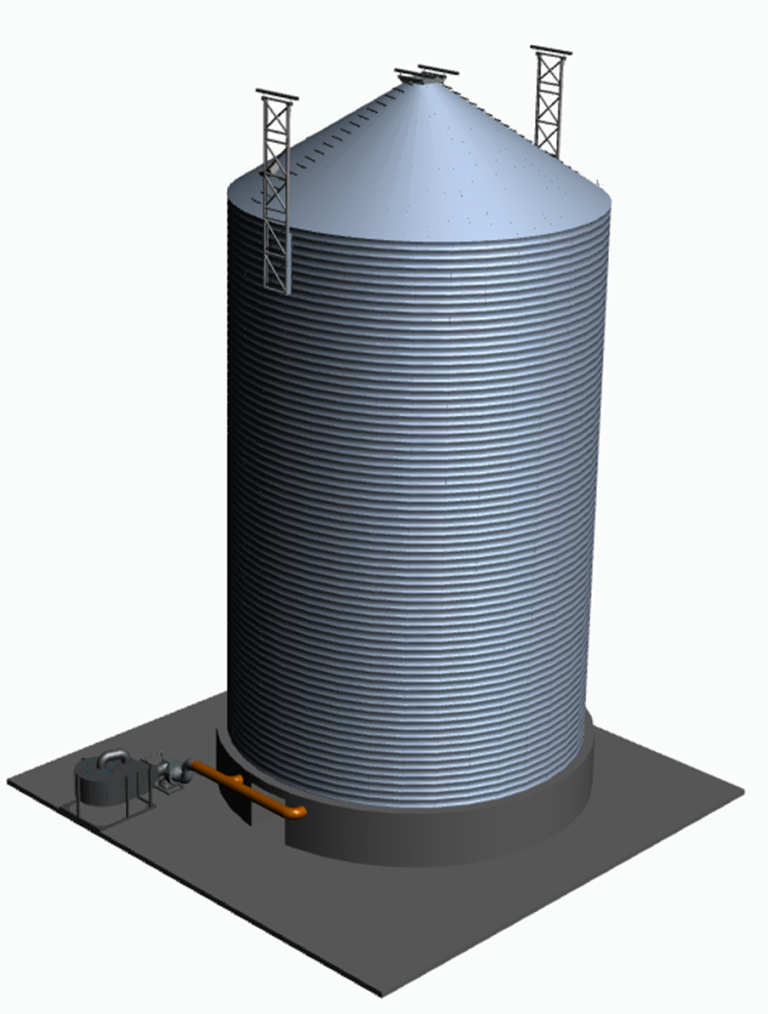

For the expected dust emission during the filling of vertical silos, the use of a suction-based, bottom-mounted solid particle separator is recommended.

Connection of a centrifugal dust separator to the vertical grain storage, in suction mode