PRODUCTS

Development of a Flow-Optimised Bucket Elevator

The accumulation of contaminants can be represented by a deposition curve of a similar shape for most types of crops. The key factors influencing the deposition process are the cleanliness and moisture content of the crop, as well as the length of operating time. The extent of accumulation varies between different crops, as it is defined by the characteristic agrophysical properties of the crop particles.

The elevator head is a critical component of the elevator’s design, as the harmful phenomena described earlier are caused by fluid flow anomalies occurring within the elevator head. To eliminate these anomalies, the newly developed bucket elevator head features a homogeneous pressure distribution, reduced turbulence, and targeted geometric modifications.

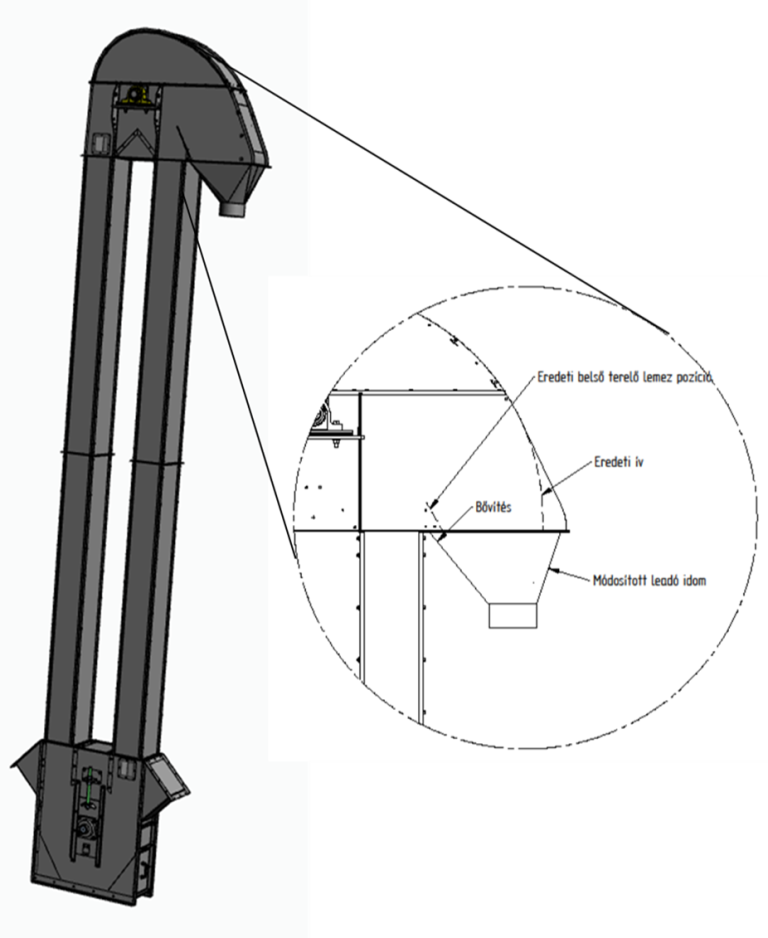

As a result of the development, the accumulation of deposits in the newly designed elevator head has been reduced by 63–68%. This result was achieved by optimising the curvature of the elevator head’s front plate, increasing the internal space of the discharge fitting, and strategically widening its inner section on the elevator shaft side.

Modification of the elevator head’s external front plate, along with the internal deflector plate and discharge fitting

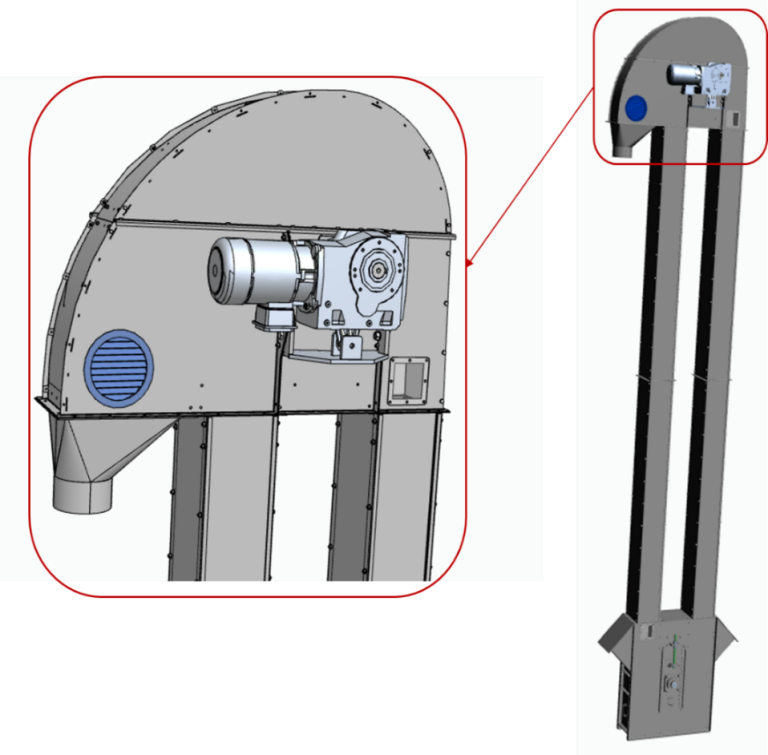

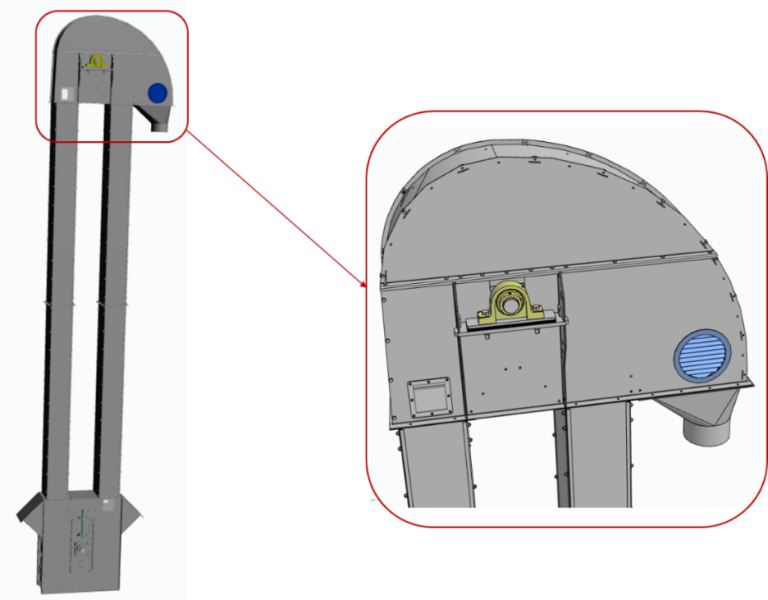

Design of ventilation grilles in the two side plates of the elevator head

We addressed the unfavourable pressure conditions by incorporating ventilation grilles into both side plates of the elevator headThe two ventilation grilles proved effective in eliminating overpressure within the elevator head and significantly reducing reverse turbulence—and, consequently, the accumulation of contaminants.

The R&D-based development of the bucket elevator has resulted in a new design that functions identically to its predecessor. Its operation and maintenance require no new knowledge compared to previous equipment, yet its technical parameters have improved significantly.